Fiber Optic Center will be at Anga Com - Schedule your meeting with a member of the FOC team now

Syringes, Tips, Pistons and Barrels, Plunger

In addition to the epoxy and adhesive materials that play a critical role reliable optical connections, the equipment and supplies are equally important including Syringes, Tips, Pistons and Barrels and Plungers.

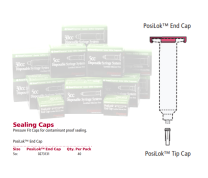

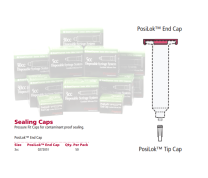

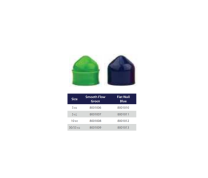

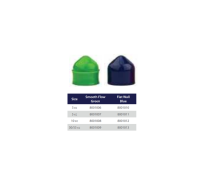

Syringes provide precise and controlled dispensing of adhesive materials. In fiber optic applications, where finite amounts of adhesive are used and precision is necessary to avoid damaging the delicate fibers, this is critical. Syringes can be fitted with different types of tips and needles, for customization in the dispensing process, ensuring consistent and high-quality results.

Tips should be compatible with the epoxy being used based on appropriate gauge size to ensure proper dispensing. The Fiber Optic Center Technical Team provides consultation for 1) choosing the right type of tips for the syringe, 2) the proper cleaning and replacement schedule to avoid contamination and ensure accurate and consistent dispensing and 3) the correct technique for attaching the tips to the syringe to prevent air bubbles or leakage.

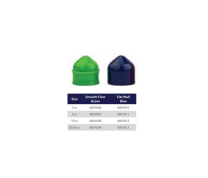

Pistons and barrels are important, as a part of a dispensing system that transfers the epoxy material from syringe to application site, because its quality and accuracy can affect the flow rate and consistency of the epoxy and ultimately the final product quality. The Fiber Optic Center Technical Team provides consultation for high-quality pistons and barrels selection that are compatible with the epoxy material being used to ensure consistent and accurate dispensing.

Epoxy plungers, used in syringes to dispense precise amounts of epoxy adhesive, are critical in contamination control. During selection, we first ensure that the plunger is made of compatible material with the epoxy being used and fits the syringe correctly to prevent any leakage or improper dispensing. Additionally, the Fiber Optic Center Technical Team offers best practices and maintenance schedules for plungers so they remain free of contaminants and debris to ensure accurate dispensing. Tips include a new plunger for each use to prevent cross-contamination between different batches of epoxy.

Read More Syringes provide precise and controlled dispensing of adhesive materials. In fiber optic applications, where finite amounts of adhesive are used and precision is necessary to avoid damaging the delicate fibers, this is critical. Syringes can be fitted with different types of tips and needles, for customization in the dispensing process, ensuring consistent and high-quality results.

Tips should be compatible with the epoxy being used based on appropriate gauge size to ensure proper dispensing. The Fiber Optic Center Technical Team provides consultation for 1) choosing the right type of tips for the syringe, 2) the proper cleaning and replacement schedule to avoid contamination and ensure accurate and consistent dispensing and 3) the correct technique for attaching the tips to the syringe to prevent air bubbles or leakage.

Pistons and barrels are important, as a part of a dispensing system that transfers the epoxy material from syringe to application site, because its quality and accuracy can affect the flow rate and consistency of the epoxy and ultimately the final product quality. The Fiber Optic Center Technical Team provides consultation for high-quality pistons and barrels selection that are compatible with the epoxy material being used to ensure consistent and accurate dispensing.

Epoxy plungers, used in syringes to dispense precise amounts of epoxy adhesive, are critical in contamination control. During selection, we first ensure that the plunger is made of compatible material with the epoxy being used and fits the syringe correctly to prevent any leakage or improper dispensing. Additionally, the Fiber Optic Center Technical Team offers best practices and maintenance schedules for plungers so they remain free of contaminants and debris to ensure accurate dispensing. Tips include a new plunger for each use to prevent cross-contamination between different batches of epoxy.

Syringes, Tips, Pistons and Barrels, Plunger

In addition to the epoxy and adhesive materials that play a critical role reliable optical connections, the equipment and supplies are equally important including Syringes, Tips, Pistons and Barrels and Plungers.

Syringes provide precise and controlled dispensing of adhesive materials. In fiber optic applications, where finite amounts of adhesive are used and precision is necessary to avoid damaging the delicate fibers, this is critical. Syringes can be fitted with different types of tips and needles, for customization in the dispensing process, ensuring consistent and high-quality results.

Tips should be compatible with the epoxy being used based on appropriate gauge size to ensure proper dispensing. The Fiber Optic Center Technical Team provides consultation for 1) choosing the right type of tips for the syringe, 2) the proper cleaning and replacement schedule to avoid contamination and ensure accurate and consistent dispensing and 3) the correct technique for attaching the tips to the syringe to prevent air bubbles or leakage.

Pistons and barrels are important, as a part of a dispensing system that transfers the epoxy material from syringe to application site, because its quality and accuracy can affect the flow rate and consistency of the epoxy and ultimately the final product quality. The Fiber Optic Center Technical Team provides consultation for high-quality pistons and barrels selection that are compatible with the epoxy material being used to ensure consistent and accurate dispensing.

Epoxy plungers, used in syringes to dispense precise amounts of epoxy adhesive, are critical in contamination control. During selection, we first ensure that the plunger is made of compatible material with the epoxy being used and fits the syringe correctly to prevent any leakage or improper dispensing. Additionally, the Fiber Optic Center Technical Team offers best practices and maintenance schedules for plungers so they remain free of contaminants and debris to ensure accurate dispensing. Tips include a new plunger for each use to prevent cross-contamination between different batches of epoxy.

ShopSyringes provide precise and controlled dispensing of adhesive materials. In fiber optic applications, where finite amounts of adhesive are used and precision is necessary to avoid damaging the delicate fibers, this is critical. Syringes can be fitted with different types of tips and needles, for customization in the dispensing process, ensuring consistent and high-quality results.

Tips should be compatible with the epoxy being used based on appropriate gauge size to ensure proper dispensing. The Fiber Optic Center Technical Team provides consultation for 1) choosing the right type of tips for the syringe, 2) the proper cleaning and replacement schedule to avoid contamination and ensure accurate and consistent dispensing and 3) the correct technique for attaching the tips to the syringe to prevent air bubbles or leakage.

Pistons and barrels are important, as a part of a dispensing system that transfers the epoxy material from syringe to application site, because its quality and accuracy can affect the flow rate and consistency of the epoxy and ultimately the final product quality. The Fiber Optic Center Technical Team provides consultation for high-quality pistons and barrels selection that are compatible with the epoxy material being used to ensure consistent and accurate dispensing.

Epoxy plungers, used in syringes to dispense precise amounts of epoxy adhesive, are critical in contamination control. During selection, we first ensure that the plunger is made of compatible material with the epoxy being used and fits the syringe correctly to prevent any leakage or improper dispensing. Additionally, the Fiber Optic Center Technical Team offers best practices and maintenance schedules for plungers so they remain free of contaminants and debris to ensure accurate dispensing. Tips include a new plunger for each use to prevent cross-contamination between different batches of epoxy.